Building Systems

combining steel and SIRCONTEC insulating foam concrete enable the affordable and fast construction of solid walls, intermediate floors and roofs with good thermal insulation and excellent fire protection and are inexpensive to invest.

OVERVIEW & PROPERTIES

SIRCONTEC participates in the development of several fast and affordable Whole-house building systems with good thermal insulation, suitable mainly for mass construction of low-cost buildings and/or in the development of optimal insulating concrete technology for them; some of them have become part of the offer:

- F-SYSTEM - walls and floors of light framed insulating panels

- MULTILAYER FILIGRAN - construction of full-wall panels with double/triple wall

- LGS FRAME SYSTEM - structures made of light gauge sheet profiles covered with boards filled with ultralight foam concrete

- STELLAR SYSTEM - a building solution from panels with steel frame embedded in insulating concrete

- CAST in-SITU - casting buildings into the formwork

All the building systems can be used both for new construction and for extensions and renovations. But each system has its range of ideal use, and these ranges usually do not match. An important fact for an evaluation is the viewpoint of the field of application.

Casting complete buildings with foam concrete into formwork (Cast in-Situ) is a type of conventional construction technology usually with lower input/investment costs compared to prefabrication and with a quick and easy start of construction implementation with a possible gradual acceleration of construction.

Other construction systems are prefabricated systems, each with a different ratio of offsite construction work to onsite construction work per square meter of built-up area. These industrial building systems are modern methods of construction (MMC) that require an initial investment in technology and production halls but offer several advantages over traditional techniques. They are less labour-intensive, have better working conditions, shorten the time of onsite construction with fewer workers, and reduce the cost of transportation, the entire construction, greenhouse gas emissions and construction waste.

F-SYSTEM

A comprehensive building system with the fastest construction of rough construction - by assembling all building structures from light insulation panels manufactured using simple, low-cost prefabrication in permanent formwork from thin-walled steel U-profile frames with a quick start of production into operation.

It is a whole house building solution represented by a precast construction modular system of construction of buildings. It combines the speed and efficiency of steel frames with the advantages of classical masonry. The precast construction F-System consists of planar panel elements which are interconnected to create a rigid and safe supporting structure. The construction system is open, and the dimensions of its elements adapt to the architectural design of a building.

F-System Elements

The Structural Elements (F-Panels) consist of three main components:

- Steel peripheral frame which determinates the shape and dimensions of a structural element and serves as a casting mould (permanent formwork).

- Steel reinforcement

- Foam concrete (cellular concrete) with a density of 750-850 kg/m³ for wall panels and 1000-1400 kg/m³ for floor/roof panels

Thanks to its simplicity, significant economical features, speed, high thermal and sound insulation and fire resistance, the F- System is extremely competitive for mass construction of schools, hospitals, housing, and habitation projects.

Together with our partners, we are providing complex design and engineering services, we can address the project from the preliminary stage till the construction.

The factories with this simple production precast technology can be erected in a brief time or the production technology can be easily installed into existing unused production halls.

MULTILAYER FILIGRAN

Is a complex building system with the fastest realization of monolithic constructions in permanent formwork made of light triple or double-walled whole-wall panels manufactured using uniquely simple, low-cost prefabrication technology with simple and quick commissioning.

It is also a building system with the highest possible level of prefabrication for the fastest possible construction completion.

Multilayer Filigree is a concept of success. The construction system includes high-quality wall empty prefabricated multilayer concrete panels, which combine the advantages of prefabricated and monolithic reinforced concrete structures.

Multilayer Filigran combines the dimensional accuracy and quality control of precast walls with the flexibility of in-situ concrete. It consists of a pair of precast reinforced concrete shells tied together with steel trusses and is usually filled with in-situ concrete on-site or with the foam concrete with a density of 600 kg/m³ during MF production, creating a uniform cross-section of both prefabricated slabs and (foam) concrete core, acting statically as a monolithic reinforced concrete structure.

The Double or Triple Wall Panels combined with Filigree Slabs provide a complete monolithic smooth structure.

The Multilayer Filigree building system is suitable for any modern construction - residential construction, industrial and civic amenities, agricultural buildings, parking houses, hotels, supermarkets, schools, etc.

The main advantages of the multi-layer filigree building system include extremely fast and easy installation of all vertical and horizontal structures, the absence of classic formwork, a minimum of finishing work and easy scalability of solutions.

Advantages of the Czech Multilayer Filigree over other double-wall construction systems:

- Autoclaving system is not mandatory.

- It is not necessary to support ceilings/intermediate floors during their installation.

- Wall panels can be manufactured including a roof parapet. This feature enables and significantly speeds up erecting and concreting the last storey together with a roof.

- It is possible to produce wall panels with foam concrete filling. In addition to increasing the wall's thermal resistance, it speeds up on-site concreting.

- Easy learning - quick start-up.

- Short delivery time.

- Low initial investment in technology.

The factories with this simple production precast technology can be erected in a short time or the production technology can be easily installed into existing unused production halls.

LGS FRAME SYSTEM

Allows for ease of installation and fast delivery even of incredibly challenging construction projects. It provides ecological, economical, and technological advantages in comparison to all other known types of construction systems. It is affordable, fast, and eco-friendly.

The structure consists of light-gauge steel (LGS) frame structure made of cold-formed steel with cement or glass fibre cement (GFRC) boards cladding and SIRCONTEC ultralight foam concrete infill.

Cold-formed steel (CFS)combined with SIRCONTEC foam concrete gives all the benefits of a design-led approach combined with the advantages of prefabrication and foam-concrete monolithic structure.

Light Gauge Steel Frame Structure system

The walls made of the LGS frame structure, covered on both sides with boards (cement chipboards or GFRC), form a lost formwork.

200 kg/m³ density SIRCONTEC foam concrete is poured in between the boards where it fills the internal space creating a monolithic homogeneous insulating cellular concrete wall reinforced with light-gauge galvanized steel profiles.

Construction of horizontal slabs, intermediate floors and roofs is similar to wall construction, where boards are screwed to the bottom side of the steel frame and foam concrete fills the space slab to the required level.

Cold-formed steel (CFS) offers the construction industry significant benefits throughout the design and construction process. Integrated software solutions make designing and detailing cold-formed steel quick and efficient, so deadlines and budgets can be met, and risks reduced. It is also the perfect material for prefabricating components before they go to the site - it decreases on-site work.

Summary: Using cold-formed steel (light gauge steel framing) covered on both sides with boards combined with SIRCONTEC foam concrete allows for ease of installation, fast delivery, and project completion.

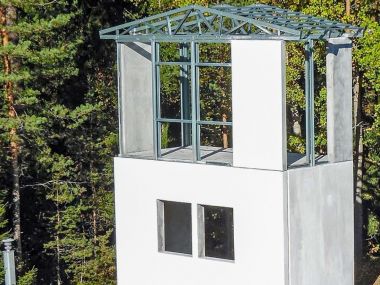

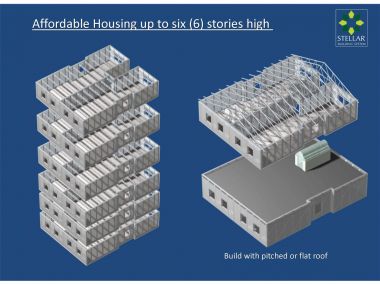

STELLAR Precast System

Makes AFFORDABLE and FAST construction possible offering a complete package: exterior walls, demising and other partition walls, intermediate floor and roof system.

STELLAR combines steel and insulating concrete with a density of 500 - 1,000 kg/m2 for a solid, rigid structural wall, while the structural steel frame is completely embedded in the insulating concrete.

It features good thermal insulation, excellent fire protection and easy on-site installation.

It is ideal for residential, light commercial and public sector construction up to five-story buildings in earthquake-prone regions of the world.

STELLAR uses SIRCONTEC foam concrete technology.

STELLAR has a high-volume production method in precast quality.

STELLAR is a whole-house construction system guaranteeing the best overall economy and fastest installed delivery to the building site.

STELLAR supplies a complete machinery package supported by hands-on training

More information is in the presentation below and the attached document(s).

CAST in-SITU

Is a reliable technology for casting buildings in-situ with foam concrete (1400 – 1200 kg/m³) into vertical, reusable, and easy (dis)mountable wall formwork.

All walls together of each building floor including a floor/roof - with steel reinforcement, openings for doors and windows and empty pipes/tubes for mechanical-electrical-plumbing (MEP) installations may be completed in one pour each day with every set of moulds; therefore, this monolithic building method is very suitable for mass construction of the same or similar buildings, e.g., for mass construction of houses, schools, hospitals, etc.

Casting of buildings with foam concrete into formwork (Cast in-situ) is a technology with the lowest production costs per square meter of built-up area, with low input/investment costs and with a quick and easy start of construction implementation with 1 to 2 sets of formwork and the corresponding number of workers. The pace of construction can be accelerated by gradual procurement - adding more formwork sets and workers.

Casting complete buildings in vertical Moulds reveals the complete range of benefits offered by air-cured foam concrete, which are:

- No plant - factory for prefabrication is needed.

- Low input costs compared to prefabrication.

- A short time from the decision to build to the start of construction.

- No need to transport ready-made prefabs - less steel reinforcement per m2 of masonry.

- Speed of completion of construction, hence the fast return of capital investment.

- Mass construction speed can be easily and quickly increased by adding the necessary amount of formwork kits and service personnel.

- High precision of dimensions given by the mould.

- No joints are necessary.

- Minimum waste of material.

- Either openings or actual frames for doors/windows cast in.

- Facility pipes/tubes (MEP installations) cast in, no damage in fitting afterwards.

- Textured surface by rubber moulds possible.

- Cutting/sawing of foam concrete possible if necessary.

Together with our partners, we are supplying complex design and engineering services, we can address the project from the preliminary stage till the construction.

SIRCONTEC participates in construction projects by supplying machinery, technology, chemical agents, and its assistance - professional consultancy, design, training, and engineering services.